Mikuni Carburetor Tuning Manual: A Comprehensive Guide

This manual unlocks the potential of your Mikuni carburetor, offering a detailed exploration of installation, operation, and crucial safety guidelines for optimal performance.

Sudco’s racing carburetor tuning manual provides a complete overview, empowering enthusiasts with the knowledge to navigate a new world of possibilities and achieve peak engine efficiency.

Mikuni carburetors have long been a cornerstone of performance enhancement for motorcycles, ATVs, and various other engines, renowned for their precision and responsiveness; This legacy stems from decades of innovation and a commitment to delivering superior fuel delivery systems.

Sudco’s Mikuni Racing Carburetor Tuning Manual serves as your gateway to understanding these intricate devices. Whether you’re a seasoned mechanic or a dedicated enthusiast, this guide will demystify the complexities of Mikuni carburetors.

From their initial development to the advanced technologies found in modern models like the TM40, Mikuni has consistently pushed the boundaries of carburetor design. This manual provides a comprehensive overview, covering installation procedures, operational principles, and, most importantly, the art of precise tuning. Understanding the fundamentals is crucial for unlocking the full potential of your engine and achieving optimal performance characteristics.

This guide will equip you with the knowledge to confidently tackle carburetor adjustments and ensure your engine runs smoothly and efficiently.

Understanding Carburetor Function

At its core, a carburetor’s function is to precisely mix air and fuel to create a combustible mixture for the engine. This process relies on Bernoulli’s principle, where airflow creates a vacuum that draws fuel into the airstream. Mikuni carburetors excel in this process due to their meticulously engineered venturi designs and responsive throttle mechanisms.

The carburetor’s components – including the float bowl, jets, needle, and pilot screw – work in harmony to regulate this mixture across varying engine speeds and loads. Each component plays a vital role in delivering the correct air/fuel ratio for optimal combustion.

Sudco’s tuning manual emphasizes the importance of understanding how each circuit within the Mikuni carburetor operates. From the pilot circuit, responsible for idle and low-speed running, to the main jet, governing high-speed performance, mastering these circuits is key to achieving a perfectly tuned engine. This knowledge empowers you to diagnose and resolve performance issues effectively.

Essential Tuning Concepts

Mastering air/fuel ratios, jetting, and pilot screw adjustments are fundamental to Mikuni carburetor tuning, unlocking peak engine performance and ensuring optimal combustion efficiency.

Air/Fuel Ratio Explained

Understanding the air/fuel ratio is paramount when tuning a Mikuni carburetor. This ratio, expressed as a numerical value, dictates the mixture’s composition for efficient combustion. A stoichiometric ratio, ideally around 14.7:1 for gasoline, represents complete combustion – theoretically, all fuel and air react perfectly.

However, engine tuning often deviates from this ideal. A rich mixture (lower numerical ratio, e.g., 12:1) contains excess fuel, providing more cooling and potentially preventing detonation, but can lead to fouling and reduced efficiency. Conversely, a lean mixture (higher numerical ratio, e.g., 16:1) has less fuel, maximizing fuel economy and power, but risks overheating and engine damage.

Mikuni carburetors allow precise adjustments to manipulate this ratio. Jetting, needle positioning, and the pilot screw all influence the air/fuel mixture across different throttle positions and engine speeds. Accurate tuning requires recognizing the symptoms of rich or lean conditions and making corresponding adjustments to achieve the optimal balance for your specific engine and riding conditions.

The Importance of Jetting

Jetting is the cornerstone of Mikuni carburetor tuning, directly controlling fuel flow at various throttle positions. The main jet governs fuel delivery at wide-open throttle, while the pilot jet manages the mixture at idle and low speeds. The needle jet and jet needle work in conjunction to regulate fuel flow during mid-range throttle openings.

Selecting the correct jet sizes is crucial for optimal performance. Undersized jets (lean condition) can cause overheating and engine damage, while oversized jets (rich condition) lead to fouling, poor fuel economy, and reduced power. Jetting choices depend on factors like engine displacement, altitude, temperature, and riding style;

A systematic approach to jetting involves starting with recommended baseline settings and then making incremental adjustments based on observed engine behavior. Utilizing an air/fuel ratio meter provides precise feedback, ensuring the mixture is within the safe and efficient range throughout the RPM band. Proper jetting unlocks the full potential of your engine.

Pilot Screw Adjustment

The pilot screw, also known as the fuel screw or air screw depending on the Mikuni model, fine-tunes the air/fuel mixture at idle and just off idle. Adjusting this screw impacts the carburetor’s responsiveness and smooth operation during initial throttle application;

Turning the pilot screw in restricts airflow (richens the mixture), while turning it out increases airflow (leans the mixture). The ideal setting achieves the highest stable idle speed and the smoothest transition from idle to slightly open throttle. A typical adjustment procedure involves warming the engine to operating temperature.

Start with the screw approximately 1.5 to 2 turns out from fully seated. Slowly adjust the screw in or out, listening for changes in engine speed and smoothness. Fine-tuning is essential for a crisp, responsive low-end and a stable idle, contributing significantly to overall rideability.

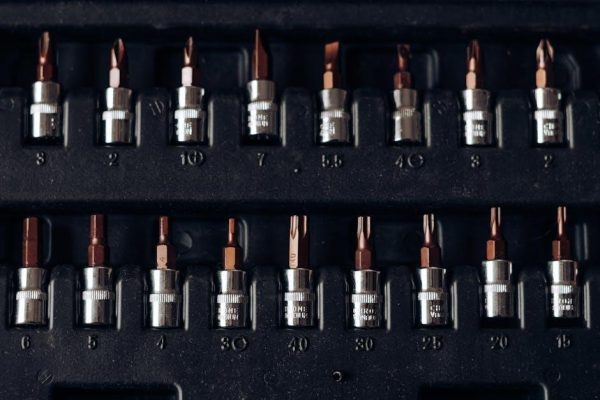

Tools and Equipment Needed

Successful tuning demands specific tools: jetting kits, an air/fuel meter for precise readings, and a tachometer to monitor engine RPMs for optimal adjustments.

Jetting Kits and Resources

Investing in a comprehensive jetting kit is paramount for Mikuni carburetor tuning, providing a range of main jets, pilot jets, and needle jets to precisely match your engine’s requirements. These kits allow for incremental adjustments, crucial for dialing in the optimal air/fuel mixture across the entire RPM range.

Beyond the kit itself, access to reliable resources is invaluable. Online forums dedicated to motorcycle performance and Mikuni carburetors offer a wealth of knowledge from experienced tuners. Manufacturer websites, like Sudco, often provide detailed specifications and jetting charts as starting points.

Consider the specific application – is it for racing, street riding, or a custom build? Different kits cater to these varying needs. Ensure the kit is compatible with your carburetor model (TM40, for example) and engine displacement. Don’t hesitate to consult with a professional tuner if you’re unsure about selecting the appropriate kit or interpreting the data.

Diagnostic Tools (Air/Fuel Meter, Tachometer)

Accurate diagnosis hinges on utilizing the right tools. An air/fuel (A/F) meter is indispensable for determining the current air/fuel ratio, revealing whether the mixture is rich, lean, or ideally balanced. Wideband A/F meters provide real-time data, crucial for precise jetting adjustments.

A reliable tachometer is equally vital, allowing you to monitor engine RPM during tuning. This ensures adjustments are made at specific RPM ranges, correlating with the carburetor’s different circuits (pilot, needle, main). Observing RPM fluctuations also helps identify potential issues like vacuum leaks.

Beyond these core tools, a quality multimeter can assist in checking electrical connections and verifying proper sensor function. Data logging capabilities, available on some A/F meters, provide a comprehensive record of tuning sessions, facilitating informed decisions and repeatable results.

Tuning Procedure: Step-by-Step

Begin with a solid baseline, meticulously adjusting each circuit – pilot, needle, and main – in a systematic sequence for optimal engine performance and responsiveness.

Initial Setup and Baseline

Establishing a precise baseline is paramount before embarking on any Mikuni carburetor tuning endeavor; Ensure the engine is warmed up to operating temperature, and all electrical connections are secure. Begin by verifying the float height within the manufacturer’s specified range; incorrect float levels drastically impact fuel delivery.

Next, confirm the throttle slides move freely and are properly weighted. A sticky slide hinders responsiveness. Install a new spark plug, gapped correctly, and check ignition timing. Record these initial settings meticulously.

Start with the pilot screw set to the factory recommended turns out from fully seated. This provides a starting point for idle mixture adjustment. Observe the engine’s behavior during startup and idle; note any hesitation, stalling, or rough running. These observations form the foundation for subsequent adjustments, guiding you towards a finely tuned carburetor.

Finally, document all initial readings and settings. This detailed record allows for accurate comparisons and facilitates reverting to the original configuration if needed during the tuning process.

Pilot Circuit Tuning

The pilot circuit governs fuel delivery at idle and low throttle openings. Begin by slowly adjusting the pilot screw, turning it in or out in small increments – typically ¼ turn at a time. Observe the engine’s response after each adjustment; listen for the highest, smoothest idle speed.

Turning the screw in restricts fuel flow, leaning the mixture, while turning it out enriches it. Aim for the leanest possible setting without causing the engine to stumble or stall. If the engine continues to stumble, even at the factory setting, the pilot jet may be too small and require upsizing.

Pay close attention to plug chops – examining the spark plug’s color – to confirm the mixture’s accuracy. A light tan or chocolate brown indicates a correctly tuned pilot circuit. Black and sooty signifies a rich condition, while white indicates a lean one.

Repeat the adjustment and observation process until the engine idles smoothly and responds crisply to slight throttle inputs.

Needle Jet and Jet Needle Adjustment

The needle jet and jet needle control the mid-range fuel delivery, impacting throttle response between idle and full throttle. Adjusting the jet needle’s clip position alters the fuel mixture in this range. Raising the clip enriches the mixture, while lowering it leans it.

Start with the clip in the middle position and assess the engine’s performance during acceleration. Hesitation or a lean surge suggests the clip should be raised, adding fuel. A rich, sluggish response indicates lowering the clip is necessary.

Consider the needle jet size if clip adjustments prove insufficient. A larger needle jet delivers more fuel, addressing consistently lean mid-range conditions. Conversely, a smaller jet is suitable for rich scenarios.

Careful observation of spark plug color and engine behavior is crucial for precise tuning. Aim for a smooth, responsive transition from idle to full throttle.

Main Jet Tuning

The main jet governs fuel delivery at wide-open throttle, crucial for maximum power and preventing engine damage. Selecting the correct main jet size is paramount for optimal performance and longevity.

Begin with a jet size recommended for your engine displacement and riding conditions. Perform wide-open throttle runs, monitoring engine behavior and spark plug color. A white or light gray plug indicates a lean condition, requiring a larger jet.

A dark, sooty plug signifies a rich mixture, necessitating a smaller jet. Incremental changes are key; increase or decrease jet size in small steps to avoid drastic alterations.

Pay attention to engine temperature and altitude, as these factors influence fuel requirements. Proper main jet tuning ensures reliable power delivery and protects against overheating or detonation.

Troubleshooting Common Issues

Diagnosing carburetor problems involves identifying rich or lean conditions, addressing idle instability, and resolving hesitation or stalling for peak performance.

Rich vs. Lean Conditions

Understanding the difference between a rich and lean condition is fundamental to Mikuni carburetor tuning. A rich mixture occurs when there’s too much fuel relative to air, often presenting as black smoke from the exhaust, a fuel smell, and potentially fouling spark plugs.

Conversely, a lean mixture signifies insufficient fuel, leading to a hotter exhaust, potential engine overheating, and a white or light gray spark plug color. Lean conditions can be particularly damaging, increasing the risk of engine seizure.

Identifying these conditions requires careful observation of spark plug appearance, exhaust color, and engine behavior. Accurate diagnosis is crucial before making any jetting or adjustment changes. Proper tuning aims for the ideal air/fuel ratio, ensuring optimal performance and engine longevity, avoiding the pitfalls of either extreme.

Consistent monitoring and adjustment are key to maintaining a healthy and efficient engine.

Idle Problems and Solutions

Addressing idle issues with a Mikuni carburetor often begins with the pilot screw. A fluctuating or unstable idle typically indicates an incorrect pilot screw setting. Turning the screw clockwise leans the mixture, while counterclockwise richens it. Small adjustments are crucial, typically ¼ turn at a time.

If the engine won’t idle at all, check for air leaks around the intake manifold and carburetor flange. Vacuum leaks disrupt the air/fuel mixture, preventing a stable idle. Ensure the float level is correct, as an incorrect level can also cause idle problems.

Persistent issues may require cleaning the pilot jet and pilot circuit to remove any obstructions. Careful diagnosis and methodical adjustments are key to achieving a smooth and reliable idle.

Remember to allow the engine to warm up fully before making idle adjustments.

Hesitation and Stalling

Hesitation during acceleration or outright stalling often points to issues within the mid-range circuit of the Mikuni carburetor. The jet needle and its associated jet needle clip play a vital role here. Adjusting the clip position alters the fuel delivery as the throttle opens.

A lean condition, indicated by hesitation, can be addressed by raising the clip (richening the mixture). Conversely, a rich condition causing stalling may require lowering the clip. Inspect the jet needle for wear or damage, as this can disrupt fuel flow.

Ensure the fuel supply is adequate and the fuel filter is clean. A restricted fuel flow can mimic carburetor issues. Carefully evaluate throttle response and adjust the jet needle accordingly for a seamless transition.

Proper synchronization with other carburetors (if applicable) is also essential.

Advanced Tuning Techniques

Mastering altitude and temperature compensation is crucial for peak performance. Synchronizing multiple carburetors ensures balanced fuel delivery, optimizing power and responsiveness across all cylinders.

Altitude Compensation

As altitude increases, air density decreases, impacting the air/fuel ratio required for optimal combustion. Mikuni carburetors, while generally adaptable, often necessitate adjustments at higher elevations to prevent a lean condition. This is because less air entering the carburetor means less fuel is needed to maintain the ideal mixture.

To compensate, consider using a larger main jet to deliver more fuel. The extent of the change depends on the altitude gain; a general rule of thumb suggests decreasing the main jet size by approximately one size for every 1,000 feet of elevation increase. However, this is a starting point, and fine-tuning is always recommended.

Pilot screw adjustments may also be necessary, particularly for lower-speed circuits. Monitoring spark plug color is a valuable indicator of mixture correctness. A white or very light tan color suggests a lean condition, while a dark, sooty color indicates a rich mixture. Careful observation and iterative adjustments are key to achieving optimal performance at varying altitudes.

Temperature Effects on Tuning

Ambient temperature significantly influences carburetor tuning, impacting fuel density and vaporization rates. Colder temperatures increase air density, requiring a richer mixture, while warmer temperatures decrease air density, necessitating a leaner setting. These changes affect both the pilot and main circuits of the Mikuni carburetor.

During colder weather, a slightly larger main jet and a small adjustment to the pilot screw (turning it out) can enrich the mixture. Conversely, in warmer conditions, a smaller main jet and turning the pilot screw in will lean the mixture. Monitoring spark plug color remains crucial for verifying the accuracy of these adjustments.

Humidity also plays a role, as higher humidity reduces air density, similar to warmer temperatures. Consistent monitoring and adjustments are vital, especially when experiencing significant temperature swings. A well-tuned carburetor adapts to these changes, delivering optimal performance across a wider range of conditions.

Multi-Carburetor Synchronization

When dealing with multiple Mikuni carburetors, precise synchronization is paramount for smooth engine operation and optimal power delivery. Uneven airflow between carburetors can lead to performance imbalances, rough idling, and reduced throttle response.

Synchronization typically involves adjusting the throttle slides to ensure equal vacuum signals to each cylinder; This is commonly achieved using a vacuum gauge connected to each carburetor’s intake manifold. The goal is to obtain identical vacuum readings across all carburetors at a specific engine speed.

Fine-tuning often requires iterative adjustments, alternating between carburetors until perfect synchronization is achieved. Proper synchronization eliminates engine vibrations, improves fuel efficiency, and maximizes the benefits of a multi-carburetor setup. Regular checks are recommended, especially after any carburetor maintenance or adjustments.